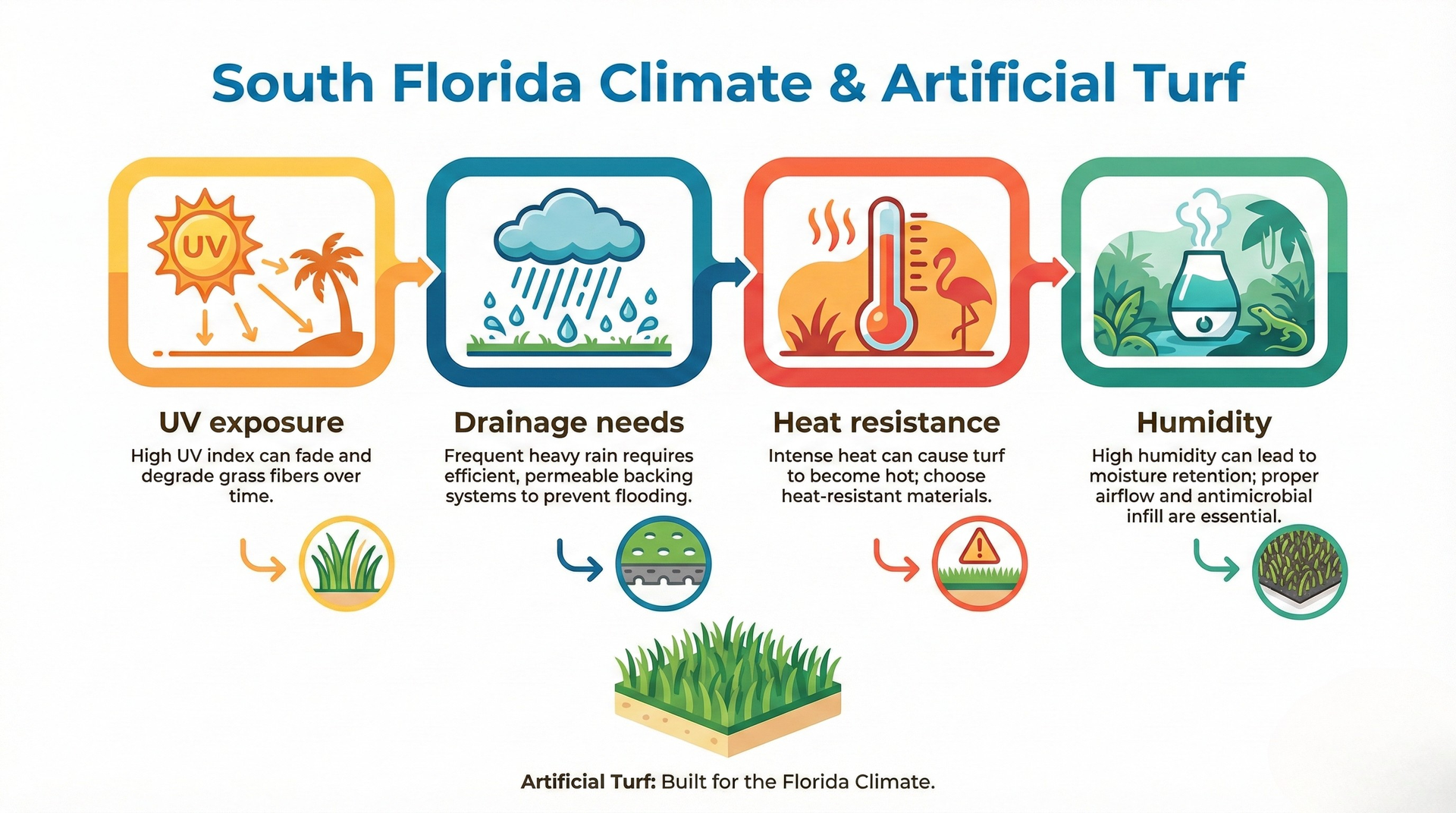

If you live in Broward or Palm Beach County, you already know our climate is not gentle on outdoor materials. Between intense sun, high humidity, heavy rain, and year‑round heat, anything you put in your yard has to work a little harder to last.

That’s why when people ask, “What are artificial grass fibers actually made of?” the better question is:

Which fiber materials actually hold up best in South Florida?

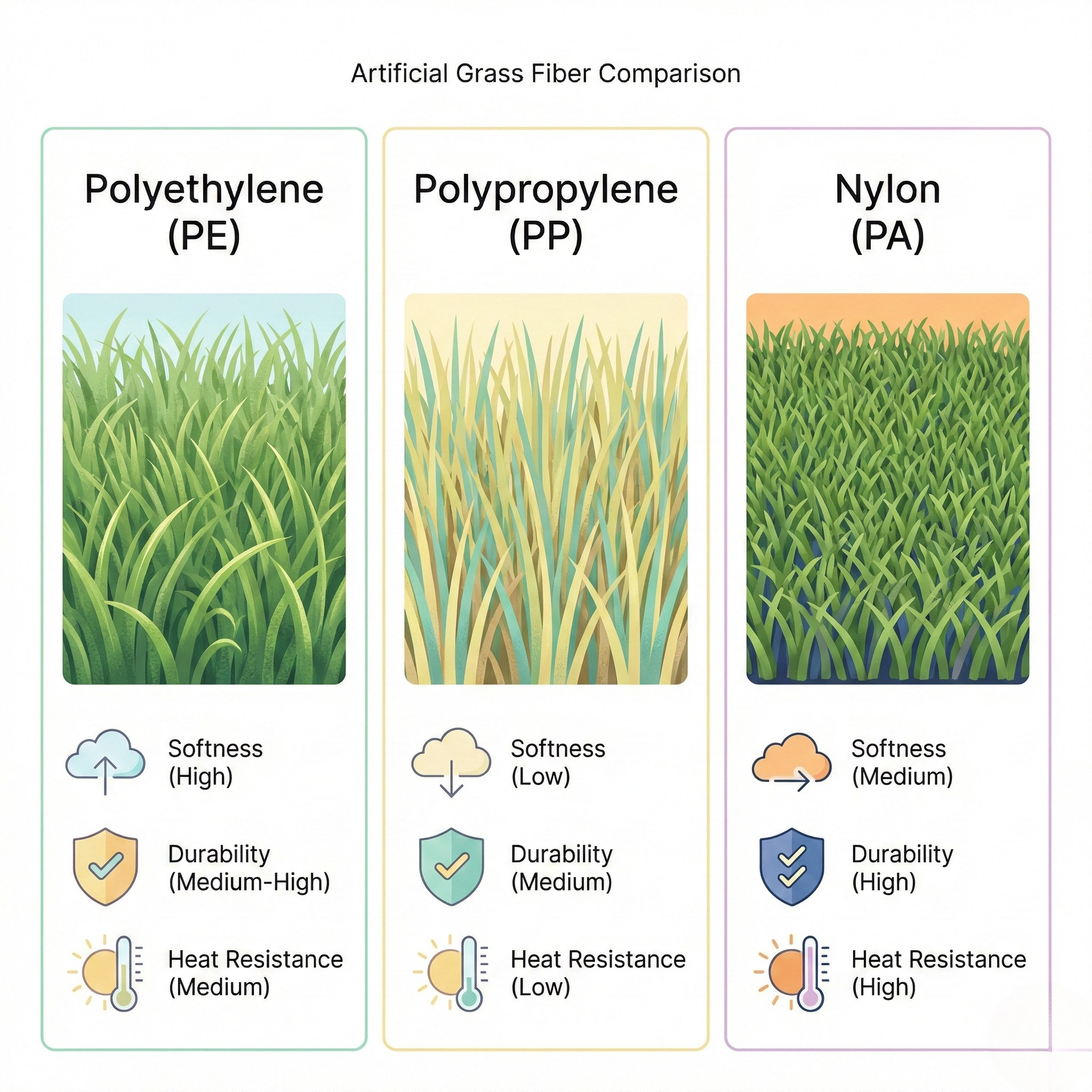

Let’s break down the three main materials used in artificial turf fibers, what they’re good at, and how they perform specifically in our local climate.

The Big 3 Materials Used in Artificial Grass Fibers

1) Polyethylene (PE) — the most common residential turf fiber

Polyethylene is the most widely used fiber material for modern artificial lawns.

Why it’s popular in South Florida:

- Softer and more natural‑looking than other plastics

- Stays flexible in heat

- Handles sun exposure well when properly UV‑stabilized

- Comfortable for kids and pets

This is usually the fiber behind turf that looks and feels closest to real grass.

Local reality check:

In our climate, not all polyethylene is created equal. The key is UV stabilizers and pigments blended into the fiber during manufacturing. Without that protection, even good‑looking turf can fade or become brittle faster under Florida sun.

2) Polypropylene (PP) — the support player (and budget option)

Polypropylene shows up in turf in two main ways:

- As a lower‑cost fiber in light‑use or decorative turf

- As the thatch layer — the short, curly fibers near the base that help blades stand up

How it performs locally:

- More heat‑sensitive than PE

- Stiffer feel

- More prone to UV wear over time

In South Florida installs, we most often see polypropylene used as thatch support, not as the primary blade fiber.

3) Nylon (PA) — the toughest, most resilient fiber

Nylon is the heavy‑duty option.

Strengths:

- Excellent resilience (springs back after foot traffic)

- High heat tolerance

- Extremely durable

Tradeoffs:

- Firmer feel underfoot

- Higher cost

Where it makes sense locally:

High‑traffic zones, commercial areas, putting greens, or small sections that get constant use.

Blended Fibers: A Smart Middle Ground

Many modern turf systems use blends (for example, polyethylene blades with nylon reinforcement or polypropylene thatch).

This helps balance:

- Soft feel

- Durability

- Heat resistance

- Cost

In South Florida, blended systems often perform better long‑term than single‑material turfs.

Why Fiber Material Alone Isn’t Enough (Especially Here)

Two turfs can both say “polyethylene” and perform very differently in Fort Lauderdale or West Palm Beach.

Here’s why:

1) UV stabilization

Sun exposure is the biggest enemy of plastic fibers. UV stabilizers dramatically affect:

- Fading

- Brittleness

- Lifespan

2) Fiber shape and construction

Blade profiles (monofilament vs tape, textured vs smooth) change:

- How hot the turf feels

- How well it stands up after rain

- How realistic it looks

3) Thatch layer design

That curly base layer:

- Adds fullness

- Improves bounce‑back

- Helps turf drain and dry faster after storms

4) Proper base + drainage installation

In South Florida, drainage prep matters as much as the turf itself.

A great fiber installed over a poor base will:

- Hold water

- Grow odor

- Shift or wrinkle

Choosing Artificial Turf Materials for Broward & Palm Beach County Homes

Not all artificial turf performs the same way in South Florida’s climate. What works well in cooler or drier states doesn’t always hold up the same in Broward and Palm Beach County, where turf is exposed to intense sun, humidity, heavy rain, and year‑round heat.

Here are a few material considerations that matter specifically for our area:

1) Prioritize UV‑stabilized fibers

In South Florida, UV exposure is the single biggest factor in fading and long‑term fiber breakdown. Whether the turf is polyethylene, nylon, or a blend, strong UV stabilization and quality pigments make a major difference in how long it keeps its color and softness.

2) Look for heat‑tolerant fiber construction

Darker, denser turf and stiffer fibers tend to hold more heat. Softer polyethylene blades and lighter color blends usually stay more comfortable underfoot during hot afternoons in Fort Lauderdale, Boca Raton, and surrounding areas.

3) Choose fiber systems that drain and dry quickly

Frequent rain means turf needs to release water fast. Blade shape, thatch design, and backing all affect how quickly turf dries after storms and afternoon downpours.

4) Match fiber material to how the space will be used

- For family yards and pet areas: polyethylene or PE‑heavy blends are usually the best balance of comfort and durability.

- For high‑traffic zones or putting greens: nylon or reinforced blends hold their shape longer.

- For decorative or light‑use areas: PP thatch combined with PE blades often performs well without overbuilding the system.

Bottom line:

For Broward and Palm Beach County homes, the

“best” turf isn’t just about fiber type — it’s about choosing materials, UV protection, blade design, and installation methods that are proven to perform in South Florida’s sun, rain, and heat.

How This Ties Into Installation and Long‑Term Cost

If you’re exploring artificial turf for your home in Broward or Palm Beach County, understanding fiber materials is just one piece of the puzzle. Proper base preparation, drainage, and professional installation play just as big a role in how long your turf lasts and how it performs in South Florida’s heat and rain.

You can learn more about what goes into a quality install on our artificial turf installation page. And if you’re weighing long‑term value, our breakdown of artificial turf cost savings explains how the right materials and installation can reduce water bills, maintenance costs, and ongoing lawn care expenses over time.

Thinking About Artificial Turf for Your Yard?

Choosing the right turf isn’t just about how it looks on day one, it’s about how it holds up years later in Florida sun, rain, and heat.

If you’re in Broward or Palm Beach County and have questions about materials, drainage, or what type of turf makes the most sense for your space, we’re always happy to share honest guidance based on real local installs.

No pressure. No sales pitch. Just practical answers to help you make a smart long‑term decision.

Final Takeaway for South Florida Homeowners

If you remember just three things:

- Most turf fibers are polyethylene, polypropylene, or nylon (or blends)

- Polyethylene is usually the best all‑around choice for residential lawns here

- UV protection and proper installation matter as much as fiber type in South Florida

The right turf system isn’t just about what the blades are made of, it’s about choosing materials and installation methods that can handle Florida sun, rain, and heat for the long haul.

What are artificial grass fibers made of?

Most artificial grass fibers are made from polyethylene, polypropylene, or nylon. Some turf products use blends of these materials to balance softness, durability, and heat resistance.

What is the best artificial turf fiber for South Florida?

For most residential lawns in South Florida, polyethylene is the most popular choice because it feels soft, looks natural, and performs well in heat when properly UV‑stabilized.

Does artificial turf fade in Florida sun?

High‑quality turf is made with UV stabilizers that help prevent fading and brittleness. In South Florida, UV protection is critical for long‑term color and performance.

Is nylon or polyethylene better for artificial grass?

Nylon is stronger and more durable but firmer and more expensive. Polyethylene is softer and more realistic, making it better for most residential lawns.

What material is used for the thatch layer in artificial turf?

The thatch layer is usually made from polypropylene. These curly fibers help support the grass blades and improve bounce‑back and drainage.

Does artificial turf get hot in South Florida?

All artificial turf can heat up in direct sun. Fiber material, color, infill choice, and airflow from proper drainage all affect surface temperature.

How long does artificial turf last in South Florida?

With proper installation and UV‑stabilized fibers, quality artificial turf can last 10–15 years or longer, even in Florida’s climate.